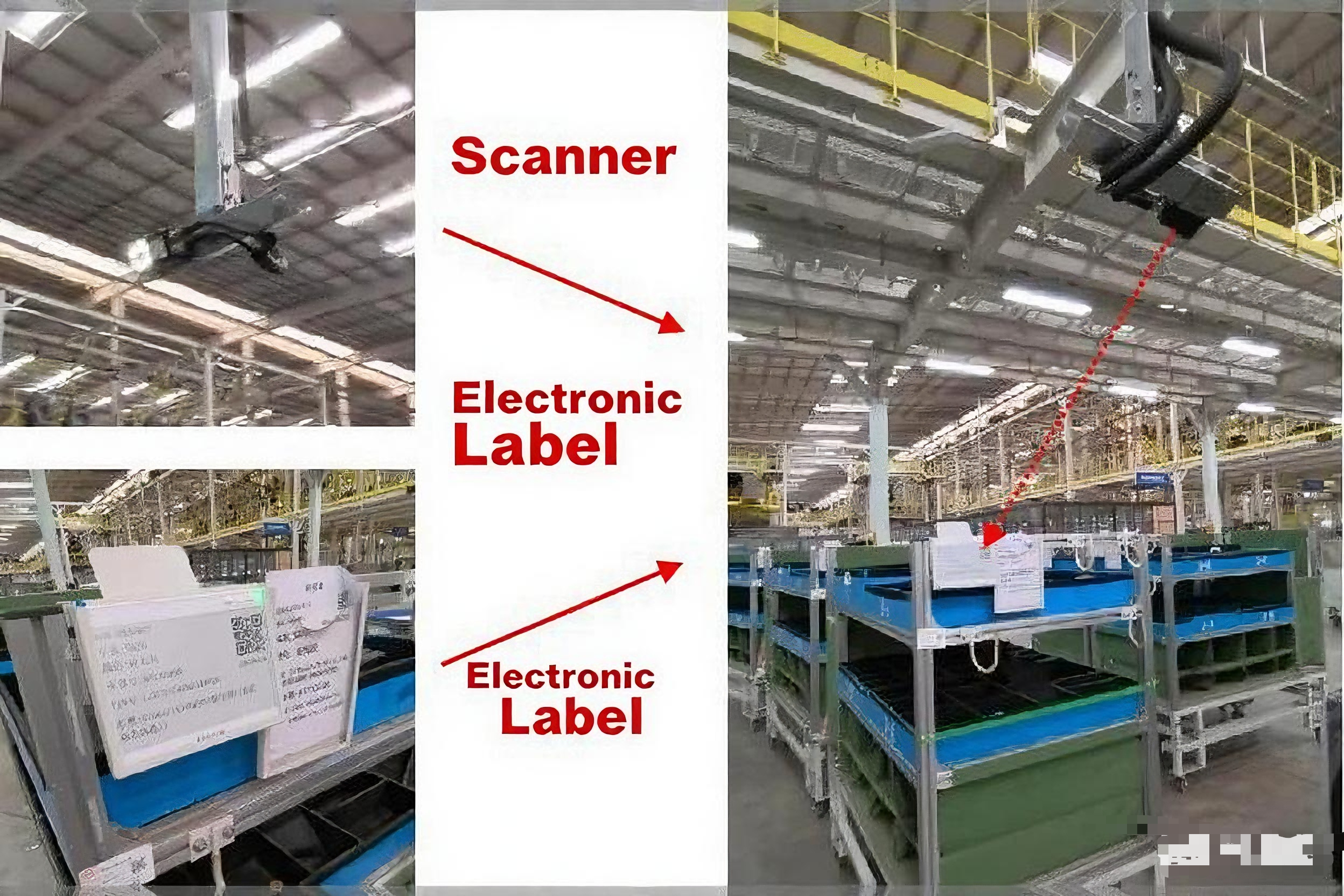

Electronic label installation

Installation of electronic tags on each turnaround vehicle, which usually contain a unique identification number and possibly other information such as current status, location, etc.

Scanner Scanning

A suspended code scanner (which may be hand-held or stationary) is used to scan electronic tags on the totes. The scanners may be wirelessly connected to allow the operator to move freely within the warehouse.

E-Ink Screen Display

Once the code scanner recognizes the electronic tag, it triggers the connected system (e.g. WMS - Warehouse Management System) to query and display the corresponding ingredient picking information on the ink screen. The ink screen is ideal for use in environments such as warehouses due to its low power consumption, high contrast and wide viewing angle.

Send data for screen casting

In addition to displaying information directly on the ink screen, the system can also cast picking data to a nearby display or mobile device. This makes it easier for operators to view high-volume data or share information with other colleagues.

Sorting operations

Operators sort and pick materials based on data displayed on ink or drop screens, ensuring that each tote is loaded with the correct ingredients.

EN

EN

FR

FR

JA

JA

RU

RU

ES

ES