In modern warehousing, automation isn’t just a productivity advantage—it’s a reliability requirement. As more industries adopt electronic picking systems, one challenge repeatedly surfaces: Can digital labels operate in low-temperature environments?

For cold-chain logistics, food storage, pharmaceutical warehouses, and frozen goods distribution, this question is critical.

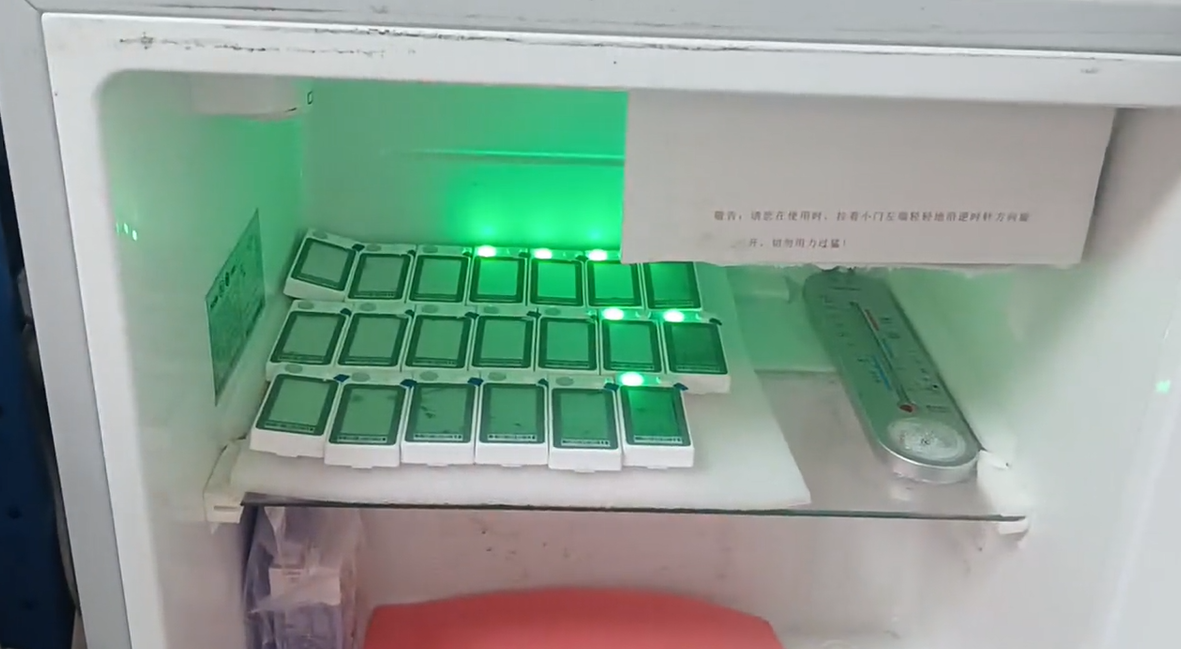

To address it, we put our warehouse picking labels under a simple but powerful test:

Place the label inside a refrigerator and observe its stability and performance over time.

The result?

A clear, steady display and flawless indicator performance—even in cold, humid conditions.

Designed for Cold-Chain Conditions

Cold environments introduce unique technical challenges:

Condensation can affect electronics

Low temperatures can slow down display refresh

Battery performance often deteriorates

Plastic casings may become brittle

Our engineered solution tackles these pain points with a robust design that maintains functionality in low-temperature scenarios. The label’s internal components and display technology are selected and optimized to deliver:

✔ Stable display performance

Even under cold, refrigerated conditions, the screen remains clear without ghosting or distortion.

✔ Reliable signal and response

The indicator light performs normally, ensuring the picking process remains smooth.

✔ Material durability

The casing retains integrity, resisting cracking or temperature-related deformation.

✔ Adaptability for cold storage workflows

Perfect for environments where products are stored between 0°C and -10°C, such as meat processing, dairy distribution, or frozen goods handling.

Why This Matters for Your Warehouse

When labels fail in low temperatures, the entire workflow slows down. Workers must manually double-check items, pick errors increase, and costs rise.

By choosing a label system designed for low-temperature performance, your operations gain:

Consistent accuracy across all storage zones

Higher picking speed with fewer interruptions

Reduced maintenance and device replacement

Better worker efficiency in refrigerated areas

Put simply:

Reliable labels in cold environments mean reliable operations overall.

Built for the Future of Temperature-Controlled Logistics

As cold-chain supply continues to grow—especially in pharmaceuticals, fresh food, and e-commerce—automation must keep up.

Our low-temperature-tolerant warehouse labels provide a future-proof solution that ensures your digital picking system remains dependable, whether in ambient storage, chilled rooms, or deep-freeze environments.

If your warehouse requires high performance where others fail, our picking labels deliver stability, durability, and confidence—every time.

EN

EN

FR

FR

JA

JA

RU

RU

ES

ES